1. Receiving raw materials: Receive various raw materials required on the day from the raw material warehouse according to the amount of raw materials on the day;

3. Melting: put the batch material into the kiln through the feeder and melt it into glass liquid according to the process requirements;

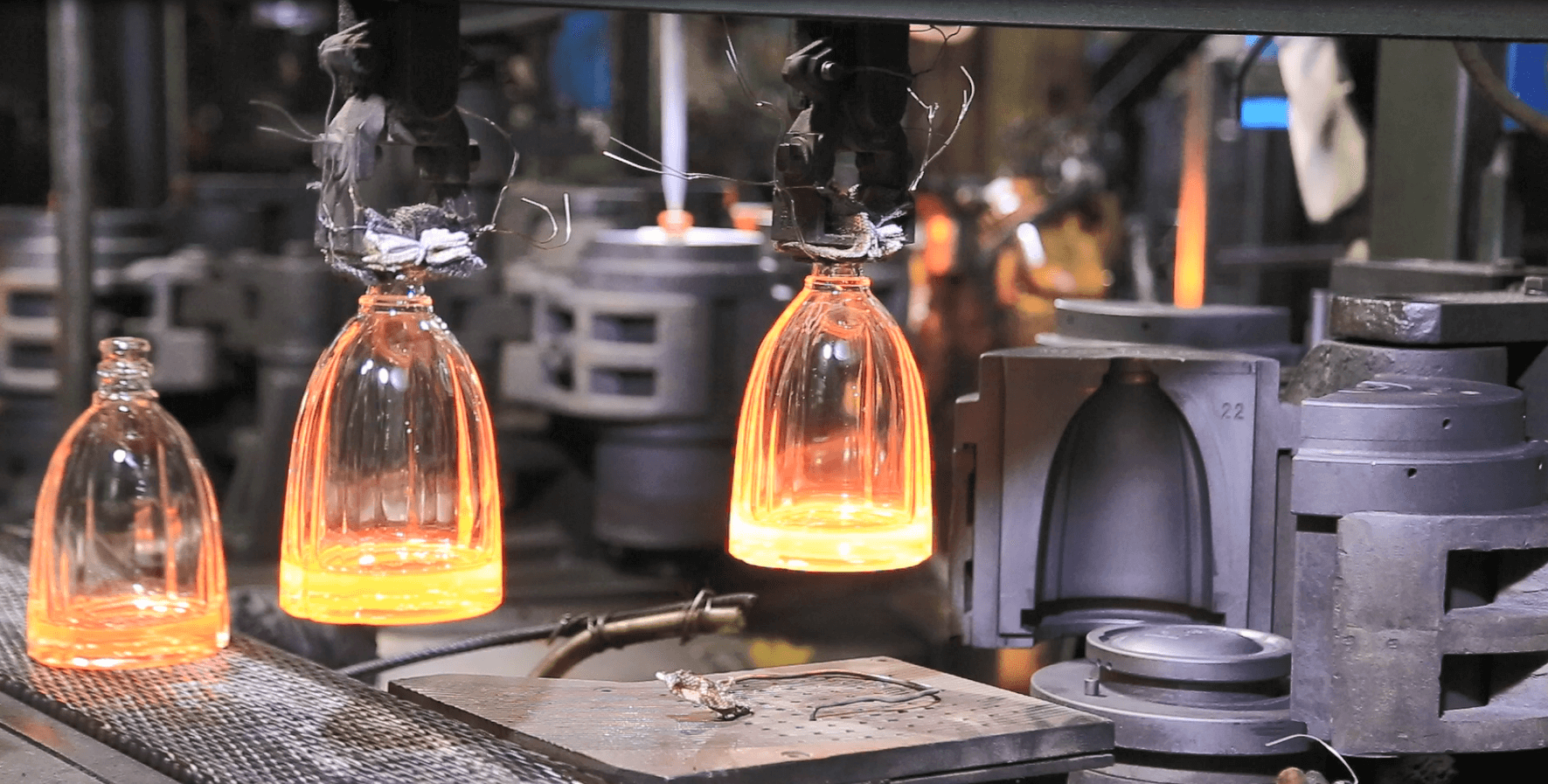

5. Blanking: The cut glass liquid is sent into the respective initial molds through the material separator;

7. Molding: Make the embryo into the required appearance size;

9. Open the mold and send the bottle: the mold is opened, and the glass products are clamped on the conveyor belt and sent to the annealing furnace;

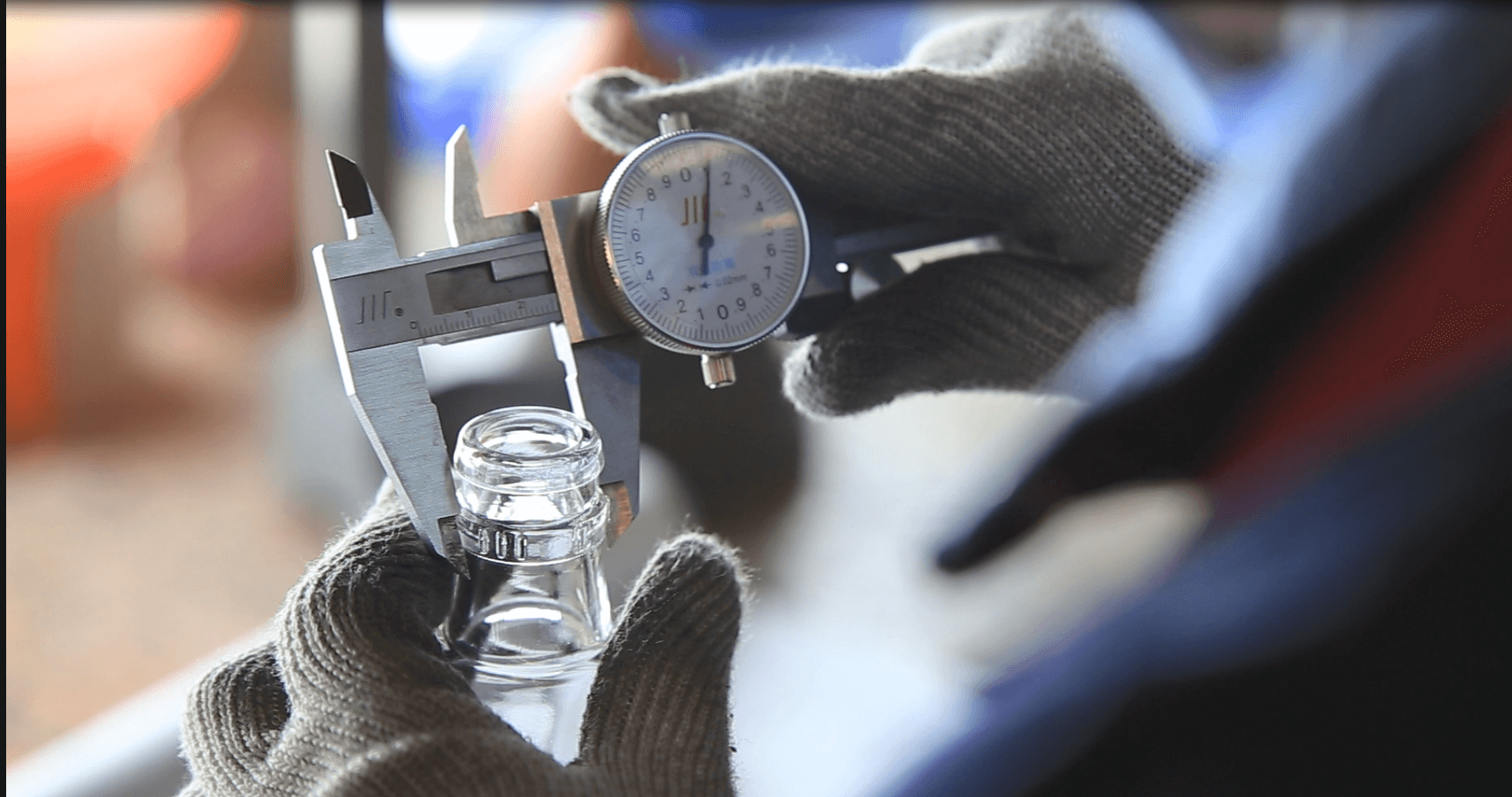

11. Inspection: carry out quality inspection on the glass products from the annealing furnace, and select qualified products;

4. Inspection: select qualified products according to the quality requirements for the painted glass products;

6. Inspection: carry out quality inspection on the products after decals, and send qualified products to the peeling furnace;

8. Baked flower: send the product with the film removed into the flower furnace, and heat it according to the process requirements to make the flower paper adhere to the product;

10. Packaging: packaging the qualified products;